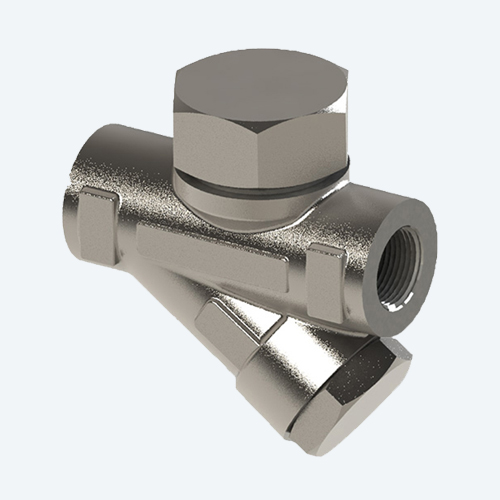

Elite Valve is a leading manufacturers, suppliers, and exporters of Thermodynamic steam traps valves in Mumbai, India. Also, we are offering valve repairs services in India. Thermodynamic steam traps are perfect for industrial applications which need maximum energy efficiency and cost savings. Designed to monitor, detect, and release steam at optimal pressure levels while also trapping condensate in a safe manner, thermodynamic steam traps provide exceptional temperature control with minimal losses.

Additionally, these innovative devices ensure proper drainage of isolated water pockets within pipes that can lead to corrosion or clogging as well as reduce erosion on internal walls of lines caused by improper draining. Versatile yet efficient thermodynamic steam traps come designed to suit any application needing hassle-free operation while offering increased safety compared with more traditional offerings. With their advanced design providing excellent flow rates due to their unrestricted passages, they’re perfect solutions whether you’re dealing with liquid flow needs or need assistance when regulating your process temperatures route from one point of origin to another destination.

Due to their compact size, big displacement, energy efficiency, long life, and low temperature resistance, thermodynamic traps are frequently employed in low, medium, and high pressure steam supply pipes, process heat tracing, and low displacement equipment.

Thermodynamic steam traps deliver superior performance and reliability in a wide range of applications.

Automatically balances air, gases & condensate ensuring efficient operation without frequent adjustments.

Integral strainer for safe steam distribution & improved product life expectancy up to 10 years or more with no maintenance!

Quality design made from stainless steel material suitable for high-pressure systems operating over an extended period of time when hot water is available/required continuously on demand?

Prevents formation of flash-steam pockets reducing energy loss in downstream pipework providing greater efficiency and cost savings compared to other types of traps solutions like mechanical floats etc.