Elite Valves is a leading Ball Valve manufacturers, suppliers, and exporters in Mumbai, India. We also offer the service of repairing all valves, such as solid, flexible, one-piece ball valves, split body ball valves, three-piece ball valves, etc in India. We have a wide range of ball valves for different applications, and industrial operations, water, wastewater management, HVAC systems, fire prevention systems, domestic plumbing, and fuel systems. It is essential to pick a reputable and dependable manufacturer that can supply high-quality ball valves that fit your specific requirements.

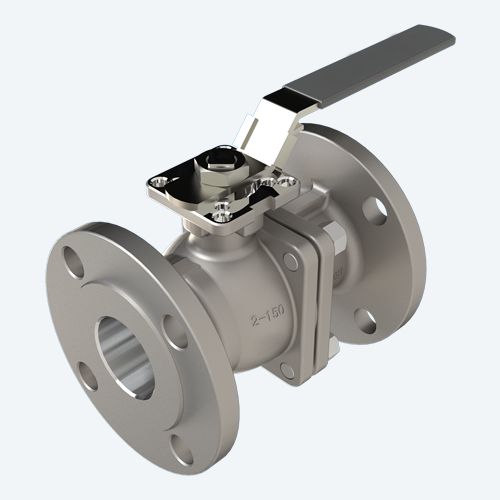

A ball valve is a valve that controls the flow of fluids or gases via a pipe by using a ball-shaped disk. When the valve is open, a hole in the middle of the ball allows fluid or gas to pass through. The valve is controlled by a lever or handle that spins the ball inside the valve body, allowing or protecting flow through the pipe. Ball valves and butterfly valve have a lot in common. Both are quarter-turn valves, which makes them easy to open. Both are considered some of the simplest control valves in the market. Both valve types can be used for on/off control and proportional control. We are manufacturer, supplier, dealer and repair service provider of ball valves in Mumbai, India.

Ball valves are an essential part of any piping system, as they control the flow of fluids passing through the pipes. Elite Valves offers a range of ball valve products that can be trusted to regulate fluid pressure in both commercial and residential environments. Our ball valves feature durable construction with precision-engineered components made from high-grade stainless steel and forged brass ensuring reliable performance year after year. Each valve is tested for quality assurance purposes before being released out into the market so you will know your purchase is fit for purpose. Our selection includes full port ball valves, multi-port design options, integrated union designs allowing for simple installation when coupled with standard pipe fittings, manual or lever-operated models, plus flanged and threaded varieties available in different sizes.

The Elite Valves 150 Class Ball Valve is a trustworthy instrument that is needed for manufacturing operations. Ball valve 150 class was designed using cutting-edge technology to ensure maximum efficiency. It consists of two parts - a body, which contains the ball that moves when operated, as well as ports connected by tubing or piping. The port sizes are normally customizable depending on the application. Its madefrom high-quality stainless steel material, this product offers excellent durability even under extreme operating conditions such as elevated temperatures and corrosive environments. Furthermore, its suitable for use in applications where complete closure is necessary without any leakage at all times.

EliteValves Co. introduces its superior grade ball valve - 300 class, designed to satisfy the most demanding applications. ball valve 300 class offers several features that boost performance and lifespan, including improved flow characteristics, improved fluid velocity, reduced pressure drop, and maximum rangeability. Furthermore, its comes with a geed structure, built of carbon steel or stainless steel, provides longer service life, making it ideal for industrial applications where corrosion resistance is a critical problem. The 100% leak resistant design assures no leaking in any working environment without sacrificing strength or dependability, even when temperatures fluctuate.

The Elite Valves 600 Class ball valve is an ideal solution for a wide range of industrial applications. Ball valves 600 class comes with High-performance, its excellent durability and strength, guarantees optimal flow control and dependable shut-off capabilities. It comes in easy to installation due to its unique design, as it requires minimal tools compared to other valves in the same class. it enhanced corrosion resistance, which drastically reduces maintenance costs overtime time compared to traditional valves products on the market today. Customers appreciate that these valves are available with almost all connection types, including but not limited too thread ends, SAE flanges and NPT threaded connections.

| Size mm (inch) | A | C | d | D | (-Wt 1) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 600 | Class 900 & 1500 | RB | RB & FB | |||||||||||||

| Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 | ||||||||||||||

| RB | FB | RB | FB | RB | FB | RB | FB | RB | FB | |||||||||

| 15 | 108 | 140 | 165 | 216 | 80 | 11 | 13 | 1.2 | 1.3 | 1.9 | 2.1 | 3.2 | 3.3 | 4.6 | 4.9 | 5.0 | 6.0 | |

| (1/2) | (4.3) | (5.5) | (6.5) | (8.5) | (3.1) | (0.4) | (0.5) | (2.6) | (3.0) | (4.2) | (4.6) | (7.1) | (7.3) | (10.1) | (10.8) | (11.0) | (13.2) | |

| 20 | 117 | 152 | 190 | 229 | 85 | 13 | 20 | 1.6 | 2.0 | 2.9 | 3.2 | 4.8 | 5.0 | 6.5 | 7.1 | 7.5 | 9.5 | |

| (3/4) | (4.6) | (6.0) | (7.5) | (9.0) | (3.3) | (0.5) | (0.8) | (3.5) | (4.4) | (6.4) | (7.1) | (10.6) | (11.0) | (14.3) | (15.7) | (16.5) | (20.9) | |

| 25 | 127 | 165 | 216 | 254 | 90 | 20 | 25 | 2.3 | 2.7 | 3.9 | 4.3 | 6.5 | 6.7 | 8.8 | 13.0 | 10.0 | 14.0 | |

| (1) | (5.0) | (6.5) | (8.5) | (10.0) | (3.5) | (0.8) | (1.0) | (5.1) | (6.0) | (8.6) | (9.5) | (14.3) | (14.8) | (19.4) | (28.7) | (22.0) | (30.9) | |

| 32 | 140 | 178 | 229 | 280 | 105 | 25 | 32 | 3.4 | 3.8 | 5.2 | 5.8 | 8.4 | 9.0 | 12.5 | 21.0 | 16.0 | 23.0 | |

| (1 1/4) | (5.5) | (7.0) | (9.0) | (11.0) | (4.1) | (1.0) | (1.3) | (7.5) | (8.4) | (11.5) | (12.8) | (18.5) | (19.8) | (27.6) | (46.3) | (35.3) | (50.7) | |

| 40 | 165 | 190 | 241 | 305 | 110 | 32 | 38 | 4.8 | 5.0 | 7.5 | 8.1 | 13.0 | 14.0 | 20.0 | 28.0 | 23.0 | 29.0 | |

| (1 1/2) | (6.5) | (7.5) | (9.5) | (12.0) | (4.3) | (1.3) | (1.5) | (10.6) | (11.0) | (16.5) | (18.0) | (28.7) | (30.9) | (44.1) | (61.7) | (50.7) | (63.9) | |

| 50 | 178 | 216 | 292 | 368 | 135 | 38 | 49 | 6.8 | 8.2 | 9.3 | 10.8 | 16.0 | 21.0 | 27.0 | - | 32.0 | - | |

| (2) | (7.0) | (8.5) | (11.5) | (14.5) | (5.3) | (1.5) | (1.9) | (15.0) | (18.1) | (20.5) | (23.8) | (35.3) | (46.3) | (59.5) | - | (70.5) | - | |

| 65 | 190 | 241 | 330 | 419 | 155 | 49 | 64 | 10.5 | 15.5 | 13.5 | 21.5 | 25.0 | 30.0 | - | - | - | - | |

| (2 1/2) | (7.5) | (9.5) | (13.0) | (16.5) | (6.1) | (1.9) | (2.5) | (23.1) | (34.1) | (29.8) | (47.4) | (55.1) | (66.1) | - | - | - | - | |

| 80 | 203 | 283 | 356 | - | 170 | 65 | 76 | 16.5 | 18.5 | 24.5 | 30.0 | 33.0 | 38.0 | - | - | - | - | |

| (3) | (8.0) | (11.1) | (14.0) | - | (6.7) | (2.6) | (3.0) | (36.0) | (40.8) | (54.0) | (66.1) | (72.8) | (83.8) | - | - | - | - | |

| 100 | 229 | 305 | 432 | - | 205 | 76 | 100 | 24.0 | 32.0 | 40.0 | 50.0 | - | - | - | - | - | - | |

| (4) | (9.0) | (12.0) | (17.0) | - | (8.1) | (3.0) | (4) | (53.0) | (70.5) | (88.2) | (110.0) | - | - | - | - | - | - | |

| 150 | 267 | 403 | 559 | - | * | 100 | 152 | 40.0 | 58.0 | 68.0 | 139.0 | - | - | - | - | - | - | |

| (6) | (10.5) | (15.9) | (22.0) | - | * | (4) | (6.0) | (88.0) | (128.0) | (150.0) | (306.0) | - | - | - | - | - | - | |

| 200 | 292 | 419 | - | - | * | 152 | 203 | 73.0 | 95.0 | 152.0 | 226.0 | - | - | - | - | - | - | |

| (8) | (11.5) | (16.5) | - | - | * | (5.7) | (8.0) | (161.0) | (209.0) | (335.0) | (278.0) | - | - | - | - | - | - | |

| 250 | 330 | 457 | - | - | * | 187 | 252 | 122.0 | 153.0 | 194.0 | 275.0 | - | - | - | - | - | - | |

| (10) | (13.0) | (18.0) | - | - | * | (7.4) | (9.9) | (269.0) | (337.0) | (428.0) | (606.0) | - | - | - | - | - | - | |

| 300 | 356/6102 | 502 | - | - | * | 228 | 305 | 146.0 | - | - | - | - | - | - | - | - | - | |

| (12) | (14/242) | (19.8) | - | - | * | (9.0) | (12.0) | (322.0) | - | - | - | - | - | - | - | - | - | |

| Body / End piece | Carbon Steel ASTM A216 Gr. WCB / Stainless Steel ASTM A351 Gr. CF8/CF8M/CF3/CF3M/CN7M / Duplex |

| Ball / Stem | Stainless Steel ASTM A217 Gr. CA15/ASTM A351 Gr. CF8/CF8M/CN7M/ASTM A276 Type 410/304/316/Duplex |

| Seat | PTFE/CFT/GFT / DELRIN / NYLON/PEEK/METAL |

| Stem Washer | GFT / Grafoil |

| Stem Seal / Body Seal | Grafoil |

| Lever | Steel |

| Body Studs / Nuts | ASTM A193 Gr. B7/ ASTM A194 Gr. 2H |

| Size mm (inch) | A | B | C | d | D | ( Wt 1) | |||

|---|---|---|---|---|---|---|---|---|---|

| RB | FB | RB | FB | RB | FB | RB | FB | ||

| 8 | 64 | 64 | 120 | 120 | 80 | 08 | 08 | 0.7 | 0.7 |

| (1/4) | (2.5) | (2.5) | (4.7) | (4.7) | (3.1) | (0.3) | (0.3) | (1.5) | (1.5) |

| 10 | 64 | 64 | 120 | 120 | 80 | 11 | 11 | 0.7 | 0.7 |

| (3/8) | (2.5) | (2.5) | (4.7) | (4.7) | (3.1) | (0.4) | (0.4) | (1.5) | (1.5) |

| 15 | 64 | 64 | 120 | 120 | 80 | 11 | 13 | 0.7 | 0.8 |

| (1/2) | (2.5) | (2.5) | (4.7) | (4.7) | (3.1) | (0.4) | (0.5) | (1.5) | (1.5) |

| 20 | 70 | 75 | 120 | 145 | 85 | 13 | 20 | 0.9 | 1.5 |

| (3/4) | (2.8) | (3.0) | (4.7) | (5.7) | (3.3) | (0.5) | (0.8) | (2.0) | (3.3) |

| 25 | 88 | 88 | 145 | 145 | 90 | 20 | 25 | 1.6 | 2.0 |

| (1) | (3.5) | (3.5) | (5.7) | (5.7) | (3.5) | (0.8) | (1.0) | (3.5) | (4.4) |

| 32 | 105 | 105 | 145 | 175 | 105 | 25 | 32 | 2.2 | 3.1 |

| (1 1/4) | (4.1) | (4.1) | (5.7) | (6.9) | (4.1) | (1.0) | (1.3) | (4.8) | (6.8) |

| 40 | 114 | 114 | 175 | 175 | 110 | 32 | 38 | 3.5 | 4.7 |

| (1 1/2) | (4.5) | (4.5) | (6.9) | (6.9) | (4.3) | (1.3) | (1.5) | (7.7) | (10.4) |

| 50 | 130 | 145 | 175 | 300 | 135 | 38 | 50 | 4.9 | 8.5 |

| (2) | (5.1) | (5.7) | (6.9) | (11.8) | (5.3) | (1.5) | (2.0) | (10.8) | (18.7) |

| Body / End piece | Forged Carbon Steel ASTM A105/ Stainless Steel ASTM A182 Gr. F304/F316,ASTM A351 Gr. CF8/CF8M/CF3/CF3M/CN7M, Duplex |

| Ball / Stem | Stainless Steel ASTM A276 Type 410 / 304/316/A20/Duplex |

| Seat | PTFE/CFT/GFT/DELRIN / NYLON / PEEK / METAL |

| Stem Washer | GFT / Grafoil |

| Stem Seal / Body Seal | Grafoil |

| Lever | Steel with PVC Sleeve |

| Body Studs / Nuts | ASTM A193 Gr. B7/ASTM A194 Gr. 2H |

| Surface Protection for Carbon Steel Valves | Base phosphating. Additional External Coating : Smoke Grey Synthetic Enamel |